Kstopa intelligent manufacturing

+Technical service

- Intelligent Manufacturing Solution Query

- Design, assembly、debugging

- Upgrade, transformation、maintenance

Flexible intelligent equipment

+Standard components

- Micro streamline module

- Streamline module

- Feeding module

- Rack module

- Universal module

- General standard parts

General standard equipment

+Smart finance

- Intelligent integrated archive library

- Financial Intelligence Vault

- Smart Money Box

- Passport Identify Terminal

+specialty robots

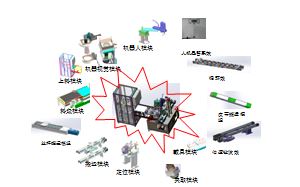

Flexible Intelligent and Precise Assembly line

The assembly line is made of a number of units. The products, are loaded and positionedon pallets are transported on conveyer belts. Assembly units are connected one to the other byconveyer belts. One single unit is built to do one step or several steps of assembly job.Products are assembled after due processes from the assembly line. The machine is madeready that we can operate from an APP installed in our cell and PAD.

一 Applied Range:

1、consumer electronics(ex:cell phone, pad computer and cameras)

2、Vehicle(ex:automobile, rile transit)

二 Characteristics

1、 Stablility & Relibility

Every unit of the assembly line is a standalone stacking system, composed by parts feeder,machine vision unit, pallets / conveying / positioning unit and industry robots.

The machine vision units measures parts and body of products being assembled, captures feature including its color, the coordinates of body of product, parts being assembled and therobot is now implemented. By computing offset of elements, the machine achieves excellentquality of assembly accuracy.All parts and units of are proven to be reliable after long periodof time practice.

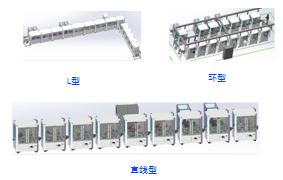

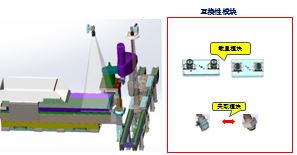

2、Universality Interchangeability Low cost for remodel Collinear production

When process of assembly is changed, all unit are re assigned to new layout and reconnected from the standard mechanical and electrical ports. We can increase and decrease number ofunits,assign them to the shop layout, even use one unit only.

Units are assigned based on its function, with its integrated control unit and standard electrical and mechanical port. When products are assigned, what have to be replaced only includes pallets,loading panels and clamping fixtures. Therefore, what’s abandoned are only pallets, loading panels and clamping fixtures when we come to new products.

The result is considerable low cost when we come to new items being assembled.

3、Cooperativity Expandability

Data is sent form BUS to center controlling system. The system integrates production and testing data backup, production data email notification, packing ID management, ERP data port and production real-time monitoring. We achieve here production coordination.

The informatization and intelligentialization of the assembly line is ready to implement future upgrading according to your needs to come into AGV logistic, intelligent warehousing and intellectual manufacturing.

- 资料 Download